Maverick and Comet Repair

Emission Controls

HEATED AIR INTAKE SYSTEM

The heated air intake portion of the air cleaner consists of a

thermostat (1970-72 models) or bimetal switch (1973-77 models), and

vacuum motor (1973-77 models), and a spring-loaded temperature

control door in the snorkel of the air cleaner. The temperature

control door is located between the end of the air cleaner snorkel

which draws in air from the engine compartment and the duct that

carries heated air up from the exhaust manifold. When under hood

temperature is below 90°F, the temperature control door blocks off

under hood air from entering the air cleaner and allows only heated

air from the exhaust manifold to be drawn into the air cleaner. When

under hood temperature rises above 130°F, the temperature control

door blocks off heated air from the exhaust manifold and allows only

under hood air to be drawn into the air cleaner.

By controlling the temperature of the engine intake air this way, exhaust emissions are lowered and fuel economy is improved. In addition, throttle plate icing is reduced, and cold weather drivability is improved from the necessary leaner mixtures.

Temperature-operated duct and valve assembly

Vacuum-operated duct and valve assembly

DUAL DIAPHRAGM DISTRIBUTORS

Dual diaphragm distributors are installed

in most 1970—77 models. The best way to check for a dual diaphragm

distributor is to count the number of vacuum hoses attached to the

distributor vacuum chamber. One hose means you have a single

diaphragm distributor, and two hoses denotes a dual diaphragm unit.

The dual distributor diaphragm is a two-chambered housing which is mounted on the side of the distributor. The outer side of the housing is a distributor vacuum advance mechanism, connected to the carburetor by a vacuum hose. The purpose of the vacuum advance is to advance ignition timing according to the conditions under which the engine is operating. This device has been used on automobiles for many years now and its chief advantage is economical engine operation. The second side of the dual diaphragm is the side that has been added to help control engine exhaust emissions at idle and during deceleration.

The inner side of the dual diaphragm is connected by a vacuum hose to the intake manifold. When the engine is idling or decelerating, intake manifold vacuum is high and carburetor vacuum is low. Under these conditions, intake manifold vacuum, applied to the inner side of the dual diaphragm, retards ignition timing to promote more complete combustion of the air fuel mixture in the engine combustion chambers.

PORTED VACUUM SWITCH

(DISTRIBUTOR VACUUM CONTROL VALVE)

Ported vacuum

switches have been used in most 1970-77 models to switch vacuum

signals with varying engine coolant temperatures. They may have two,

three, or four vacuum ports, and, on 1975-77 models equipped with a

catalytic converter and Thermactor air pump system, a set of

electrical contacts. On some late model configurations, there may be

as many as three or four separate ported vacuum switches, each with

their own special function. PVS switches may be used to switch

vacuum signals on an ignition spark control system to improve cold

start drivability or lower emissions, to cut off exhaust gas

recirculation until a predetermined engine coolant temperature is

reached, to vent Thermactor air pump air to the atmosphere under

certain engine conditions, to regulate a vacuum operated heat

control valve in the exhaust manifold, or (especially on air

conditioned cars), to provide extra ignition advance and subsequent

higher idle speed should the engine begin to overheat.

SPARK DELAY VALVE

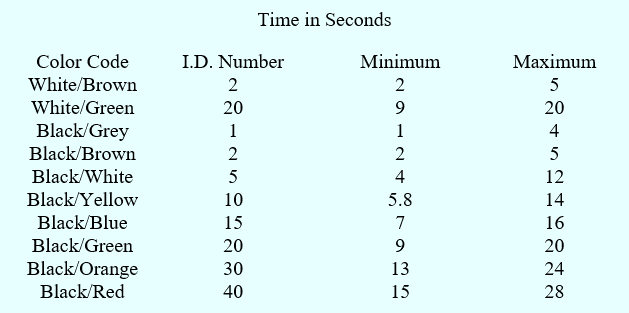

The spark delay valve is a plastic, spring-loaded, color coded valve

which is installed in the vacuum line to the distributor advance

diaphragm on many 1972-77 models. Under heavy throttle application,

the valve will close, blocking normal carburetor vacuum to the

distributor. After the designated period of closed time, the valve

opens, restoring the carburetor vacuum to the distributor. The

following chart illustrates the spark delay valve applications.

Spark Delay Valve

Distributor Modulator

(Dist-0-Vac) System

1971 Mavericks and Comets equipped

with a 200 or 250 six-cylinder engine and automatic transmission are

equipped with a Dist-O-Vac spark control system. This system is used

in conjunction with all of the IMCO system equipment, except the

deceleration valve which is no longer used.

The three components of the Dist-O-Vac system are the speed sensor, the thermal switch, and the electronic control module. The electronic control module consists of two sub-assemblies: the electronic control amplifier and the three-way solenoid valve.

The speed sensor, a small unit mounted in the speedometer cable, contains a rotating magnet and a stationary winding which is insulated from ground. The magnet, which rotates with the speedometer cable, generates a small voltage which increase directly with speed. This voltage is directed to the electronic control amplifier.

The thermal switch consists of a bimetallic-element switch which is mounted in the right door pillar and senses the temperature of the air. The switch is closed at 58°F or lower, and open at temperatures about 58°F. This switch is also connected to the electronic control amplifier.

Within the electronic control module case, there is a printed circuit board and an electronic amplifier. The speed sensor and thermal switch are connected to this assembly. The thermal switch is the dominant circuit. When the temperature of the outside air is 58°F or lower, the circuit is closed, so that regardless of speed, the electronic control amplifier will not trigger the three-way solenoid valve. At temperatures above 58°F, however, the thermal switch circuit is open, allowing the circuit from the speed sensor to take over and control the action of the solenoid valve.

The three-way solenoid valve is located within the electronic control module and below the printed circuit board of the amplifier. It is vented to the atmosphere at the top, and connected at the bottom to the carburetor spark port (small hose) and the primary (advance) side of the dual-diaphragm distributor (large hose). The large hose is also channeled through the temperature-sensing valve. The small hose is equipped with an air bleed to provide a positive air flow in the direction of the carburetor. The air bleed purges the hose of vacuum, thus assuring that raw gasoline will not be drawn through the hose and into the distributor diaphragm.

When the thermal switch is closed (air

temperature 58°F or lower), or when it is open and the speed sensor

is not sending out a strong enough voltage signal (speeds below

approximately 35 mph), the amplifier will not activate the solenoid

valve and the valve is in the closed position, blocking the passage

of air from the small tube through the large tube. With the valve in

this position, the larger hose is vented to the atmosphere through

the top opening in the three-way valve assembly. Consequently, no

vacuum is being supplied to the primary diaphragm on the

distributor, and, therefore, no vacuum advance.

When the air

temperature is above 58°F and/or the speed of the car is sufficient

to generate the required voltage (35 mph or faster), the valve

opens, blocking the vent to the atmosphere while opening the vacuum

line from the carburetor spark port to the primary diaphragm of the

distributor.

Typical Dist-O-Vac system installation