Mechanical Advance Recurved

After reading about changing the advance curve in the Dura-spark II distributor I thought I would change mine to see if it really made that much difference in performance. Since I had the perfect test subject...a low compression emission engine from the mid '70s. With all the factory retarded valve and ignition timing the engine was advertised when new at a whooping 91 horsepower.

I have already changed my timing chain gears to the straight up pre-emission a few months earlier. This swap along with swapping to the DS II did help some enough to feel a little on the butt-o-meter.

After recurving the mechanical advance to get more advance in at a lower rpm the extra power is something to talk about. I wish I had dyno runs for solid proof. This has to be the best bang for the bucks you can do for seat of the pants gain and it also improves gas mileage if you can quit playing with the new ponies.

Changing the springs on the advance weights wasn't as hard as some people clam it to be but I did remove the distributor to work on the bench just incase I dropped a small part. It is also a lot easier to work on the bench than bending over a fender.

Before removing the distributor I put the engine at top dead center and made sure the rotor was pointing to #1 cylinder. I scribe a mark on the reluctor so I'll know where it needs to be going back together. I cut an allen wrench to aid in driving the roll pin from the reluctor.

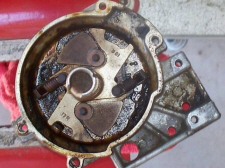

After removing the base plate to expose the centrifugal weights I replaced the light gauge spring with a even lighter gauge spring from Mr. Gasket, part #925D. Bend the tab inward 3/32 in. and replace the heavy spring. Before installing the base plate lubricate the friction points before assembling the distributor.

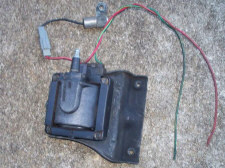

Here is a video showing how loose my distributor was